"What is the Craft Maltsters Guild?"

Here's how Brent Manning —a Craft Maltsters Guild board member and a representative of Riverbend Malt House of North Carolina— answered that question, and others I had, at the recent Craft Brewers Conference in Washington, D.C.

Manning:

The Guild is an association of North American craft maltsters with similar values and ideals maltsters even though we have had inquiries from Central and South America and small operations in Europe.

All of these people are making malt using different varieties of grain, using different equipment, some of it is homespun, a lot of it is homespun. And it's pretty exciting, because this is searching for new flavors. The tie-in for all of it is regional sourcing, support for your farmers, and transparency of quality commitment.

- YFGF:

Why has the traditional malt industry been concentrated in the upper Midwest, but the craft' malting industry elsewhere?

Manning:

The northeast used to be America's grain basket until we headed west due to consolidation, land costs, and economies of scale. The upper Midwest has fantastic growing conditions: the soil is rich, the topsoil is deep, the yield per acre is much higher than in other areas. You're looking at 125 bushels an acre in America's heartland; 75 in the South.

In the Pacific Northwest, and Idaho and Montana, it's more traditional grain-growing areas. Elsewhere, there was some disease pressure early on before we had a robust plant breeding program at public universities. The schools and a couple of private individuals are bringing in some really exciting new varieties to the market. Just giving that sense of place as you move region to region; everybody's choosing their own way of doing business.

And in the Southeast we did not have that food-grade supply chain in place. We've been really working to try and suss that out and support it, so that we can make this industry grow.

- YFGF:

I see a lot of 'craft' maltsters in the Northeast. Why is 'craft'malting developing so robustly there?

Manning:

There other things you're seeing. Brewery density is one reason you don't see craft malthouses in certain regions. Another is laws. New York State has a very expansive farm-brewery law that is tying a set of legal benchmarks to brewing and ingredients. They're great. They're fantastic, but that explains the density in New York state relative to anywhere else.

- YFGF:

And elsewhere?

Manning:

Yes. For instance, I'm the salesman for Riverbend Malt, in North Carolina. North Carolina has nothing that helps the craft malt industry. So, I'm just a crazy man right now. Whenever I walk the halls, they say, "So tell me about the hops business." I'm not talking about hops; I'm talking about barley. And North Carolina grew twenty-thousand acres of it, but it all goes into the feed market. So, it's a complicated conversation to help bridge that gap.

- YFGF:

Anyone from Georgia using 'craft' malt [home territory to YFGF]?

Manning:

Well, Riverbend has a couple of folks: Wrecking Bar Pub, a little bit with Sweetwater. Pretty much anybody who's doing the farmhouse-focused stuff. The malt really carries a lot of flavor, so it tends not to work well with IPAs. Because you want a neutral flavor or preferably nothing!

- YFGF:

How do craft maltsters incentivize farmers to grow brewing barley?

Manning:

In the South, we grow winter grains: plant in October and harvest in June. So, I'm not disrupting their normal cash-crop schedule. That makes my job easier. Up north, they are competing with some of the higher price per bushel cash crops. So the price per bushel in the northeast is higher than it is in the south because of that competitive landscape.

But, yes, cash is king. If we want someone to take a risk, we have much more stringent specs than the feed-grade industry. So, yes, we use cash as a way to incentivize.

The other thing, too, is that we want to pull them out of the commodity loop, as well. We try to agree on a variety, agree on specs, agree on a price before the grain is even planted. So, we don't really care what sort of geopolitical events might take place during the growing season that might negatively or positively affect that price point. Because it's set.

It helps everybody involved. Farmers thought we were kind of crazy at first because we were shunning these global markets that they had gotten up and checked every day for ten, twenty years. We said, no, we don't want to do business like that. We want to do business with a handshake and, hopefully, as little paperwork as possible to get these projects in motion.

- YFGF:

How do craft maltsters get their product to brewers?

Manning:

Everyone is wearing a lot of hats right now. An owner might also be the accountant, might also be the floor grain raker, might be everything in between. The industry is still in that early stage right now. Only one of our member maltsters uses a distributor. That's Pilot Malthouse in Michigan; they use BSG. Everyone else self-distributes. For most of us, it's door-to-door sales.

- YFGF:

Do craft maltsters emphasize base malts or specialty malts?

Manning:

It totally depends. At Riverbend, we do heirloom and specialty malts. The South, for example, has a long history of growing some pretty tasty raw materials that could be used in the brewing industry. It's pretty exciting to bring those into production.

- YFGF:

I'd assume sourcing equipment had been a difficult thing at first, most of it sized for much larger malting houses.

Manning:

It still is. We have people with a lot of different backgrounds. I was a stream wetland biologist before so I don't really understand the mechanics of the machinery, but understand what's going on in the kernels. But other malt houses have engineers, fabricators that they've worked with on other projects on their farm, or whatever, so they will work together, and noodle through some ideas and come up with equipment design.

That's part of why we [at Riverbend] did floor malting, obviously. It took out one of the big mechanical problems, which is how do you turn it? A guy pulling a rake, a guy with a shovel full of malt. It may not work perfectly day one, but you continue to refine it and improve upon it.

- YFGF:

Some in the 'craft' hop industry are forming cooperatives. Is 'craft' malt doing that?

Manning:

We're not so much working in that space. Geography is challenging; everybody wants to make their own products. There's not the same need for centralized equipment processing and product testing. Everyone is getting grain from different farmers.

- YFGF:

Does the Guild advocate best practices?

Manning:

We are about to release a quality and safety manual for start-up malt houses, not pushing them into 'hassip' [HACCP: Hazard Analysis and Critical Control Point] but a series of following the process from planting, the growing season, the harvest, the testing phase. That is one thing about growing grain in these non-traditional areas. Those quality specs are absolutely essential. Some farmers will get it done; some of them will not. We're trying to educate.- YFGF:

You're here at the Craft Brewers Conference. Does the Guild work with the Brewers Association?

Manning:

Right now we have a really beautiful relationship with the BA. One of their technical guys is on our board as well. There's a really nice exchange of information between quality, flavor, quantities. Really looking at the supply chain issues, it's not just the farmer and the malt house and the brewer. There's seed cleaning, trucking, and storage, and all those pieces of the puzzle that all have to be lock-step if this is going to work.

- YFGF:

Does the Guild have meetings?

Manning:

Yes. In fact, we're about to have our annual meeting, here at the Conference. Usually, between 60 to 80 people show up. We have a few tiers of membership, everything from our regular members —which are ou our producers— to the associate level which could be a malthouse in planning to allied trade. We're pretty well formalized. We have some great information on our website. We do a pretty exciting webinar series for members, which is part of our quality management and training. It's pretty specific: for instance, smoking the malt.

- YFGF:

Smoking the malt? I hear that's legal in some states now.

Manning:

It is! [Laughs]

- YFGF:

Good luck at your meetings. Thanks for answering my questions.

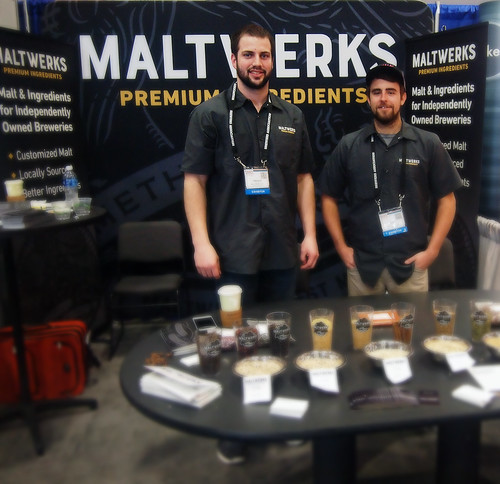

There were, in fact, a few other booths at the 2017 Craft Brewers Conference devoted to 'craft' malting, such as this 'craft' maltster, from Minnesota. And there was a seminar on field trials of barley and malt for the 'craft' brewing industry.

For a heretofore hop-centered industry, that's a welcome pivot.

-----more-----

- To create a more logical flow of the transcript, I've edited it somewhat from the audio (most of which allows YFGF to seem less fumbling). a

- Also at its Craft Brewers Conference booth, the Craft Maltsters Guild was demonstrating a newly approved malt flavor assay. See that: here.

- There have been field trials of barley, specifically grown for 'craft 'brewers, on a larger scale. Devlopments were discussed at a CBC seminar. Photos: here.

- YFGF's more general report on the CBC: here.

- For more from YFGF:

- Follow on Twitter: @Cizauskas.

- Like on Facebook: YoursForGoodFermentables.

- Follow on Flickr: Cizauskas.

- Follow on Instagram: @tcizauskas.

No comments:

Post a Comment

Comment here ...