The number one problem affecting 'craft' beer in the United States is not the beer itself. It's not the infantilization of beer flavors (Ninkasi: make it stop!). It's not even shelf-stability, although beer staling within days of receipt in a store is indeed a problem.

The biggest fault in 'craft' beer is the much-too-often-encountered poor condition of draught beer, as it is poured at pubs and at breweries themselves. Dumping pints of foam down a bar drain, repeatedly, is a gross loss of profit; it's an alteration to the carbonated quality of the beer itself. If a brewery cannot understand the basics of draught technology sufficiently enough to pour a good pint in its own taproom, how can it expect or demand that a commercial account do better?

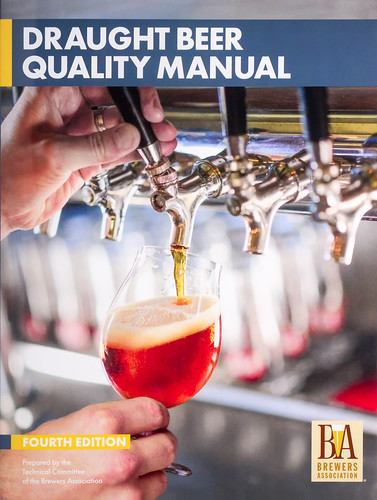

To that end —even though it wouldn't couch it in those terms— the [U.S.] Brewers Association released the 4th edition of its Draught Beer Quality Manual, in April of this year. The new edition has been expanded from the 87 pages of the 3rd edition to 117, adding an index, among other things.

Prepared by the Technical Committee of the Brewers Association, the Draught Beer Quality Manual presents well-researched, detailed information on draught line cleaning, system components and design, pressure and gas balance, proper pouring technique, glassware sanitation, and other valuable advice from the experts. Also included is information on both direct- and long-draw draught systems, important safety tips, and helpful visuals for easy reference.

The manual even contains four pages —as one of four extensive appendices— on serving cask ale. Taproom managers would be well-served to read those before simply tossing (ugh!) a firkin onto a bartop.

The Brewers Association Draught Beer Quality Working Group began focusing on draught beer quality at retail in 2007. Under the guidance of Ken Grossman, Founder of Sierra Nevada Brewing Co. and 2008 Chair of the Brewers Association Technical Committee, the brewing community came together to develop a set of best practices and standards to help brewers, wholesalers, retailers, and draught system installers improve and maintain the quality of available draught beer. The Draught Beer Quality Manual continues to evolve through collaborative efforts within the brewing community.

The information on how to serve a good —if not perfect— pint is out there; it's been so for years. There simply is no good excuse for bartenders (and brewery taprooms, for #$%!@! sake) to claim ignorance and serve bad draught beer. It's their product. They should take pride in it.

-----more-----

- The BA's press release concerning the Draught Beer Quality Manual: here.

- How to get the Manual:

- This post originally appeared on YFGF's Facebook page, in shortened form.

- Related news:

- Bridget Gauntner of Bell’s Brewery, Inc. has been named as the new chair of the BA Draught Beer Quality subcommittee, which is part of the Technical Committee structure.

— Brewers Association, 25 March 2019. - [U.S.] Brewers Association Board of Directors member Larry Horwitz has been named co-chair of the BA Technical Committee. John Mallett, longtime chair of the Technical Committee, is stepping down once he terms off the board at the end of 2019.

— Brewers Association, 2 April 2019.

- Bridget Gauntner of Bell’s Brewery, Inc. has been named as the new chair of the BA Draught Beer Quality subcommittee, which is part of the Technical Committee structure.

- For more from YFGF:

- Follow on Twitter: @Cizauskas.

- Like on Facebook: YoursForGoodFermentables.

- Follow on Flickr: Cizauskas.

- Follow on Instagram: @tcizauskas.

When I worked behind the bar at Starr Hill I would take time to train new bar staff on how to pour a pint properly, and if it was foaming like mad I would check the system and adjust the CO2 if necessary. If everything was right in the system I would take the beer off and make sure the cellar staff knew there was an issue with that particular keg.

ReplyDeleteWhat worries me more than the piss poor standard of many a pint in the US is the number of bars and taprooms that proudly trumpet their Cicerone qualified staff. What is the point of the certification if the end product is still sub-par?