Since 1997, Cask Marque has been ensuring that the cask ale you drink in pubs in the U.K. has been in perfect condition. Qualified assessors make over 20,000 visits to pubs each year in England, Scotland, Wales, and Europe to check the temperature, appearance, aroma, and taste of Britain’s favourite drink.

—Cask Marque

Does your American pub (or brewery taproom or brewpub) serve a "great pint" of cask-ale? If so, you should know that

Cask Marque accreditation

IS now available for pubs and breweries in the United States.

In fact,

Cask Marque has been assessing American pubs for several years, initially led by Paul Pendyck, a

purveyor of cask-ale equipment in the U.S. and assisted by Alex Hall, a

cask-ale partisan in New York. Both, by the way, are British expats.

Now, Steve Hamburg, one of the

premier cellarmen in the U.S., has taken the reins as

Cask Marque's USA

Director and

Chief Assessor.

****************

Criteria

What does it take for a pub (or brewery taproom or brewpub) to gain accreditation in the U.S.?

First and foremost, as self-evident as this may sound, your pub

must serve cask-ale every day, or close to it. Simply tossing a cask up on the bar once a week for

Firkin Friday doesn't cut it.

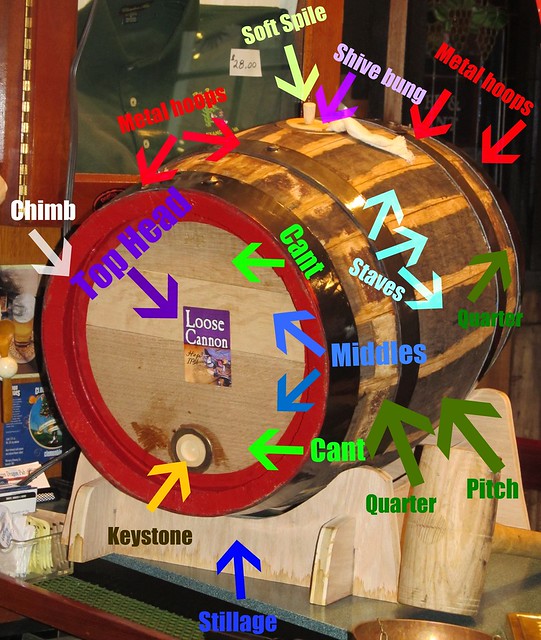

After that, it's the big five criteria: temperature, aroma, taste, appearance, and cleanliness.

- Temperature of beer.

- Real ale 1 should be served, in the customer's glass, at between 11 and 13 °C. That's 51-55 °F. (And here in the U.S., we could lower that to 10 °C / 50 °F.) That's not warm, it's cellar cool: neither too cold to mask a beer's flavor nor too warm to rob a beer of refreshment. (Unfiltered beer that is served too cold can could also develop a 'chill haze' as proteins come out of solution, which speaks to 'clarity,' discussed below.)

- Aroma of beer.

- No evidence of staling, contamination, or otherwise off-aromas that don't belong in the beer as brewed.

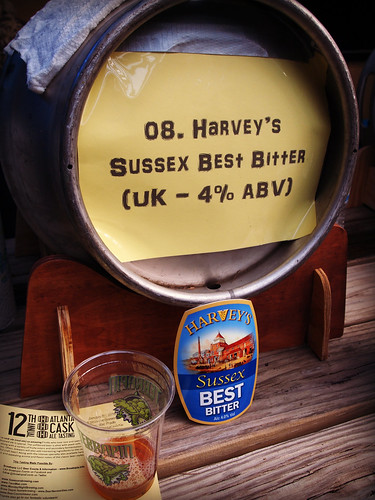

- Clarity of beer.

- This one gets tricky. As classically presented in the U.K., cask-ales should be bright as a filtered beer without filtration. But American brewers often eschew clarity (and some UK brewers do as well). So, as with aroma, the clarity should be as the beer was brewed. No extraneous yeast or proteinaceous sludge.

- Flavor (& conditioning) of beer.

- Not gassy or foamy; not flat. No evidence of staling or age. The flavor should be representative of the beer as brewed; conditioning (carbonation) should be as the brewery intended.

- Cleanliness.

- A clean beer-cellar, clean beer-lines, clean beer-engine and/or tap, and beer-clean glassware. Of course.

- NO extraneous gas pressure

- NO gas pressure can be used to dispense from the cask, whether CO2, nitrogen, or whatever. That being stipulated, a cask breather 2 does not add pressure to a cask and, thus, a pub may employ one if it wishes. Using a cask breather is not a demerit: only badly served cask-ale is.

When your pub passes its inspection, it receives a

Cask Marque metal plaque, with an attached expiration date tag. This works as does a car license plate. A pub must renew each year (and pass its subsequent assessments) to get a new valid sticker.

l-r: Paul Nunny —Director, Cask Marque (UK);

l-r: Paul Nunny —Director, Cask Marque (UK);

Steve Hamburg —USA Director, Chief US Assessor Cask Marque (US);

Paul Pendyck —Owner, UK Brewing Supplies (US).

At Craft Brewers Conference in Washington, D.C., 2017.

****************

Value to pub

Most pub owners are very money conscious, as, of course, they should be. And, yes, there is a nominal annual fee for

Cask Marque accreditation, which helps defray the cost of the U.S. licensing fee and materials. Thus pub owners should view

Cask Marque as a valuable value-added business-augmenter.

It's a consultation: how to do things right so that customers return for repeat pours. It's an advertisement of achievement, just as a victory at the

Great American Beer Festival would show brewing skill or a

Cicerone accreditation highlight serving acumen. It's a public acknowledgment of a pub's (or brewery's or brewpub's) cask excellence and, thus, of the value to a customer. And it's not (yet) a common thing in the U.S.: again a mark of distinction for your pub or taproom.

For further details, and to arrange an assessment, contact Mr. Hamburg directly, via email:

shamburg@cask-marque-americas.com.

Serving a great pint of cask-ale is not rocket science. But it does require care and attention to detail.

So, do it. Be that cask-ale hero. Get your pub its

Cask Marque accreditation. That

Cask Marque plaque is a damned nice thing to display.

-----more-----